What Happens to Failed Prints? Our End-of-Year Recycling and Upcycling Routine

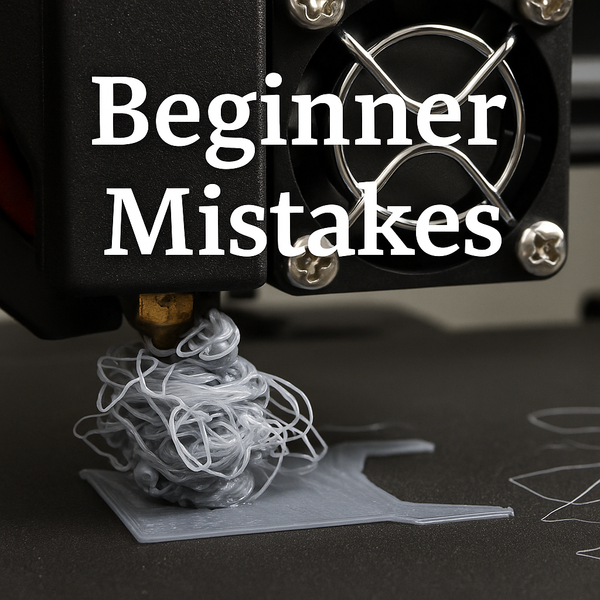

Failed prints happen to every maker. Even the best printers in the world can have a rough day. A loose nozzle, a tangled spool, a missed layer, power flicker, or a random spaghetti incident can turn a perfect print into a pile of scraps.

It happens more often during the holidays because our print farm runs longer hours and produces a larger number of items. Instead of tossing plastic in the trash, we follow a simple recycling and upcycling routine at NerdMatter3D that keeps waste low and helps us give old prints a second life.

Here is how we handle it.

Why Prints Fail More During December

Holiday production has its own challenges.

• many long multi-color jobs

• constant AMS activity

• more filament swaps

• back-to-back print queues

• temperature swings

• heavy use of every machine

Even a tiny issue can cause a print to fail. The important part is what you do with the leftovers.

Step 1: Sorting the Waste

When a failed print comes off the bed, we categorize it. Sorting makes recycling easier and prevents contamination between materials.

We sort into:

• purge blocks and color towers

• failed prints that are mostly intact

• scraps from supports

• edge trimmings

• brittle failures from cold drafts

• flexible TPU scraps

• PETG failures

• misprints from multi-color jobs

Keeping PLA, PETG, and TPU separate makes the next steps cleaner.

Step 2: Removing Hardware

Some items include embedded pieces such as:

• magnets

• fasteners

• NFC stickers

• wire loops for ornaments

We remove these with pliers before recycling. This prevents metal or adhesive from degrading the quality of recycled batches.

Step 3: Shredding or Cutting Down Material

We break larger pieces into smaller chunks. This helps with:

• consistent melting

• easier storage

• safe handling

• reduced space in recycle bins

Some makers use full shredders. We keep it simple by cutting scraps into smaller pieces and storing them in labeled containers by color and material.

Step 4: Upcycling Into New Items

Not every failure goes into recycling. Some become completely new pieces.

Examples include:

• turning purge blocks into keychains

• melting scraps into coasters

• creating abstract art tiles

• using leftovers to test paints or coatings

• cutting failed pieces into swatches for color reference

Upcycling is creative, fun, and a great way to showcase how nothing truly goes to waste.

Step 5: Sending PLA to a Local Recycler

PLA is biodegradable under industrial conditions. Many cities accept PLA through:

• makerspace recycling programs

• specialized eco drop-offs

• university labs

• community plastic collectors

Whenever possible, we drop off clean PLA scraps at partner locations that handle 3D printing waste.

Step 6: Regrinding for Future Prints

Some makers turn failed prints into new filament using grinders and extruders. We do not make our own filament, but we save sorted scraps for potential future recycling batches or community collection drives.

This reduces our overall footprint and keeps stray prints from ending up in landfills.

Why We Do This

Recycling and upcycling matter because 3D printing can generate a surprising amount of scrap. By running a print farm responsibly, we balance creativity with sustainability. It also teaches the next generation of makers, including NerdBaby, that materials deserve care and respect.

Final Thoughts

Failed prints are a normal part of 3D printing. What matters is how you handle them. By sorting, trimming, reusing, donating, and recycling material, you turn mistakes into something positive.

Every December, we gather our end-of-year scraps and give them a second life. It is one more way we keep NerdMatter3D sustainable and creative.

Want to Support Our Holiday Print Farm?

Every ornament, bookmark, and gift in our shop is printed with care and finished by hand.

Browse our holiday collection here:

👉 https://nerdmatter3d.etsy.com